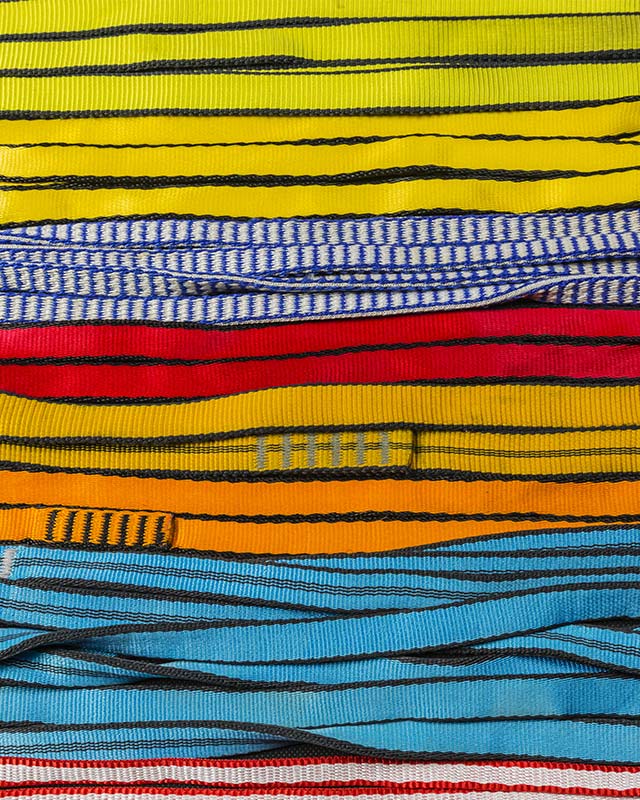

Yarns and Technical Fibres

Ribbons uses the highest quality yarns and Technical Fibres in the manufacture of all our products.

Yarn Types for webbing production

There are two main types of yarn used in the manufacture of webbing: Polyester and Nylon.

- High in strength

- Durable

- Lightweight

- Flexible

- Shrinkage resistant

- Mould resistant

- Good abrasion resistance

- Heat resistance; melting point of 256 degrees Celsius

- Low water absorption

- Quick drying

- Chemical resistance; good resistance to weak alkalis/acids, moderate resistance to strong alkalis/acids

- Controlled elongation

- High in strength

- Durable

- Good elasticity

- Good abrasion resistance

- Washable

- Quick Drying

- Flexible

- Heat resistance; melting point of approximately 215 degrees Celsius

- Chemical resistance; resists weak acids, hydrolysed by strong acids, chemically inactive to alkalis.

Technical Yarns

Ribbons have the ability to produce technical narrow fibre products to meet customer specifications. These technical yarns have the benefit of being lightweight whilst still offering exceptionally high tensile strengths, making them suitable for a diverse range of applications.

Ultra-High Molecular Weight Polyethylene fibres

Ultra-High Molecular Weight Polyethylene (UHMWPE), also known as High-Modulus Polyethylene (HMPE) and often manufactured under the brand of Dyneema®, is considered to be one of the worlds’ strongest fibres. UHMWPE yarn offers a soft, lightweight, high tensile fibre that is up to 15 times stronger than steel.

Properties of UHMWPE

- Exceptionally strong; up to 15 times stronger than steel and 40% stronger than aramid fibres

- Very lightweight

- Fire-resistant (FR)

- Abrasion-resistant

- Cut resistant

- UV resistant

- Weather-resistant

- Flexible

- Durable

- Chemical resistant; good resistance to acids/bases

Applications include

- Armour and tactical gear in the military and emergency services

- Ropes, nets and towing lines in the fishing and shipping industry

- Ropes, cords and lifting slings in industry, rescue services, and sport and leisure

- Personal Protective Equipment

- Fall protection harnesses when working at height and in sport and leisure

- Protective sleeving

Aramid Fibres

Aramid fibres, often produced under the brand name Kevlar®, are high tensile fibres known for cold resistant, heat resistant and scratch-resistant properties. 5 times stronger than steel, aramid fibres have a high tensile strength whilst being lightweight.

Properties of Aramid Fibres

- Strong; up to 5 times stronger than steel

- Lightweight

- Fire-resistant (FR)

- Extremely high heat resistance; degrades at 426-482 degrees Celsius

- Abrasion-resistant

- Flexible

- Chemically resistant in certain environments

- Controlled elongation

- Generally affected by UV light; colour and strength can degrade with prolonged exposure

Applications include

- Armour and tactical gear in the military and emergency services

- Personal Protective Equipment

- Sport and leisure, for example, paraglider suspension lines

- Ropes and cables

- Protective sleeves for optical fibre cables

- Mooring lines and other underwater applications in the marine industry

QUALITY ASSURANCE

Ribbons are fully certified to ISO 9001:2015 standard, offering full quality assurance to our customers. Our expert design team work closely with manufacturers of medical and healthcare equipment in the development of narrow fabrics based solutions. Our fully equipped laboratory offers in house testing to customer specifications.

Get In Touch

Can’t see what you’re looking for? Our research and development team work closely with customers on product innovation. Call a member of our team to discuss your requirements.

Address

Ribbons Ltd, Treorchy Ind Estate, Treorchy, CF42 6EJ,

United Kingdom

Call Us

Tel: +44 (0) 1443 432 473

Fax: +44 (0) 1443 437 413